Plastic Valves

Chemical-resistant plastic valves for aggressive media.

The special solution for special requirements

High-quality plastic valves have become established as the ideal solution for such applications. They are the first choice for regulating and controlling media where maximum resistance to corrosion and chemicals is essential for long-lasting and safe operation.

Advantages of plastic valves

Plastic valves offer numerous advantages over conventional valves made of metal or other materials:

-

Corrosion resistance: Excellent protection against rust and wear.

-

Chemical resistance: Ideal for use with aggressive chemicals.

-

High resistance: Particularly resistant to abrasive media.

-

Lightweight construction: Easier to install and handle thanks to its lower weight.

Media resistance and durability

Plastic valves are characterized by their exceptional resistance to a wide range of media types, including:

Liquid media: e.g. hydrochloric acids, aggressive cleaning agents, chlorine, alcohols.

Gaseous media: e.g. chlorine gas, ammonia, sulfur dioxide, nitrogen oxides.

Aggressive media: e.g. hydrochloric acid, sulfuric acid, various hydroxides.

These properties make them ideal for demanding industrial environments.

Versatile applications

Plastic valves offer versatile solutions across a wide range of industries. Whether in chemical processing, food and beverage production, or water treatment – these valves ensure reliable and precise process control. Their versatility and durability make them a smart choice for demanding industrial applications.

Housing materials for plastic valves

Plastic valves are available in a range of body materials, each offering distinct advantages for specific applications:

-

PVC (polyvinyl chloride): A widely used plastic known for its excellent resistance to chemicals and corrosion. PVC valves are ideal for use in aggressive environments.

-

PTFE (polytetrafluoroethylene): A high-performance plastic offering excellent chemical resistance and low friction. PTFE valves deliver outstanding performance and are ideal for applications requiring maximum resistance to corrosion and aggressive media.

-

PVDF (polyvinylidene fluoride): A thermoplastic fluoropolymer offering outstanding resistance to aggressive chemicals and elevated temperatures. PVDF valves are extremely durable and ideal for demanding industrial environments.

-

PP (Polypropylene): A versatile plastic offering high chemical resistance and mechanical strength. PP valves are lightweight, durable, and provide a cost-effective solution for a wide range of applications.

Connection types

Various connection types are available for the installation of plastic valves:

-

Adhesive connectors: Enable easy and quick connection of plastic pipes.

-

Welded sockets: Ensure a strong, leak-tight connection – ideal for demanding industrial applications.

-

Threaded sleeve: Enables quick and flexible assembly and disassembly.

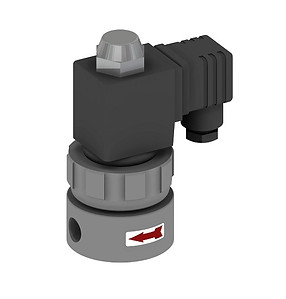

Actuation types

Plastic valves are available in various actuation types to meet diverse application requirements:

Directly-controlled

The solenoid armature closes the valve seat directly. Advantage: Reliable operation from 0 bar and fast switching times. Ideal for small nominal diameters.

Servo-controlled

A small solenoid controls the medium pressure that actuates the main seal. Advantage: Designed for high flow rates. Requires a minimum pressure differential.

104

directly controlled with separating membrane

Design 2/2-way

Actuation type direct controlled

Nominal width 1.0 mm - 2.5 mm

Pressure range 0.00 - 6.0 bar

KV value 0.5 - 2.8 l/min

Housing material PVC, PTFE

Temperature medium see pressure/temperature diagram

Connection G1/8

111

directly controlled with

Separation membrane,

liquid dampened

Design 2/2-way

Actuation type direct controlled

Nominal diameter 2.0 mm - 6.0 mm

Pressure range 0.00 - 6.0 bar

KV value 2.1 - 9.5 l/min

Housing material PVC, PTFE,

Connection threaded socket G1/4, adhesive socket d16, welding socket d16

152

directly controlled with PTFE bellows

FAQs (Frequently Asked Questions)

Plastic valves are suitable for a broad spectrum of media – including aggressive and corrosive chemicals.

-

Are plastic valves as durable as metal valves?

Yes, plastic valves are extremely durable and offer excellent resistance to many different media.

Direct-acting and servo-actuated plastic valves are available to meet the diverse requirements of various applications.

-

What types of actuation are available for plastic valves?

-

Are plastic valves suitable for use in aggressive environments?

-

Which housing materials are available for plastic valves?

Plastic valves are available in PVC, PTFE, PVDF and PP to meet the needs of different applications.

-

How can plastic valves improve the efficiency of industrial processes?

Plastic valves enhance industrial process efficiency through precise media control, outstanding durability, chemical resistance and a low-maintenance design.

Your contact for high-quality and reliable valve solutions.

WE SAY THANK YOU FOR ALMOST 70 YEARS OF TRUST.