Servo-controlled valves

Efficient control for systems

with existing differential pressure.

The operating principle: Intelligent and energy-saving

Servo-operated (also known as pilot-operated) solenoid valves cleverly utilize the existing pressure of the medium to switch. The solenoid actuator only controls a small pilot hole, after which the system pressure takes over the main work and opens the diaphragm or piston. This principle makes them ideal for switching large flow rates, provided a stable minimum pressure difference is maintained in the system.

160

servo-controlled with separating membrane

Design 2/2-way

Actuation type servo-controlled

Nominal diameter 15.0 mm - 50.0 mm

Pressure range 0.3 - 6.0 bar

KV value 3.1 - 29.6 m³/h

Housing material PVC, PP, PTFE

Connection adhesive socket, welding socket, threaded socket

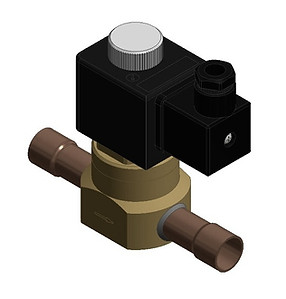

216 DN5-LR

Powerful CO2 valve

2/2-way design

Actuation type servo-controlled

nominal diameter 5.0 mm

Pressure range 0.1 - 130.0 bar

KV value 0.3 - 0.4 m³/h

Housing material stainless steel V2A

sealing material HNBR

seat seal special PTFE

Temperature Medium-40 to +150°C

ConnectionLM: solder sleeve, LM6, LM10, LM12, LM1/4, LM1/2

Technical details and areas of application

-

To help you make an informed choice, you will find an overview of the key features of servo-controlled valves here.

Advantages:

-

Energy efficiency: Since the medium does the main work, only small, energy-saving magnets are required.

-

For large flow rates: The principle enables reliable switching of large nominal diameters and high volume flows.

-

Less wear: The magnetic actuator is subjected to less stress, which leads to a longer service life of the valve.

-

Cost-effectiveness: Low energy consumption and longevity make them an economical choice.

Disadvantages:

Requires minimum pressure difference: Without sufficient pre-pressure (usually 0.1 - 0.5 bar) the valve cannot open or close.

-

Not suitable for vacuum: Due to the required pressure difference, they are unsuitable for vacuum applications.

-

Slightly slower response time: Pressure build-up takes a short moment, so they are not quite as fast as direct-acting valves.

Typical applications

Irrigation systems: Ideal for controlling water flow in agricultural or garden systems using pump pressure.

-

Heating and cooling systems: For controlling hot or cold water circuits with constant pressure conditions.

-

Industrial process control: In systems where liquids are moved with stable pressure (e.g. water treatment, chemicals) .

Maintenance and installation

-

Correct flow direction: Installation must be carried out in the flow direction marked on the housing.

-

Check pressure conditions: Ensure that the minimum differential pressure in the system is maintained at all times

"Maximum efficiency and minimal wear – servo-controlled solenoid valves for reliable and energy-saving control in every application."

Your contact for high-quality and reliable valve solutions.

WE SAY THANK YOU TRUST FOR ALMOST 70 YEARS .