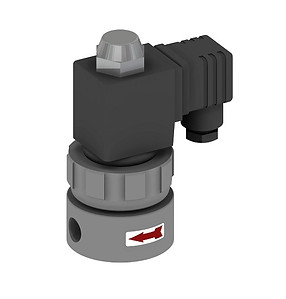

Direct-acting valves

Precise and fast control

for systems from 0 bar.

The operating principle: Direct, fast and pressure-independent

In direct-acting solenoid valves, the solenoid armature opens and closes the valve seat directly – without any detours or the need for a differential pressure in the system. This simple and robust design enables extremely fast response times and makes them the ideal choice for applications that require reliable switching from 0 bar.

111

directly controlled with

Separation membrane,

liquid dampened

Design 2/2-way

Actuation type direct controlled

Nominal diameter 2.0 mm - 6.0 mm

Pressure range 0.00 - 6.0 bar

KV value 2.1 - 9.5 l/min

Housing material PVC, PTFE,

Connection threaded socket G1/4, adhesive socket d16, welding socket d16

136

directly controlled with PTFE bellows

Design 2/2-way

Actuation type direct controlled

Nominal diameter 15.0 mm - 50.0 mm

Pressure range 0.00 - 0.5 bar

KV value 3.2 - 38.0 m³/h

Housing material PVC, PP

Connection adhesive socket, welding socket

148

directly controlled with PTFE bellows

Design 2/2-way

Actuation type direct controlled

Nominal diameter 2.0 mm - 8.0 mm

Pressure range 0.00 - 6.0 bar

KV value 1.8 - 9.0 l/min

Housing material PVC, PTFE

Pressure/temperature diagram

Connection threaded socket G1/4, adhesive socket d12

150

directly controlled with PTFE bellows

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm-20.0 mm

Pressure range 0.00 - 2.0 bar

KV value 20.7 - 53.0 l/min

Housing material PVC, PP, PTFE

Connection adhesive socket,

welding socket, threaded socket

267

Ideal for

Gas applications

Design 2/2-way

Actuation type direct controlled

Nominal width 1.0 mm - 6.0 mm

Pressure range 0.00 - 300.0 bar

KV value 0.7 - 10.7 l/min

Temperature medium -10 to +100°C

Connection G1/4, G3/8

269

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 25.0

Pressure range 0.00 - 20.0 bar

KV value 2.5 - 12.3 m³/h

Temperature medium -10 to +100°C

ConnectionG1/4, G3/8, G1/2, G3/4,

G1, G1 1/4

270

classic

Type2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 50.0 mm

Pressure range 0.00 - 40.0 bar

KV value 2.5 - 47.2 m³/h

Temperature medium -10 to +100°C

Connection See table

271

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 32.0 mm

Pressure range 0.00 - 64.0 bar

KV value 2.5 - 20.0 m³/h

Temperature medium -10 to +100°C

Connection See table

272

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 32.0 mm

Pressure range0.00 - 100.0 bar

KV value 2.5 - 20.0 m³/h

Housing materialBrass, stainless steel 1.4305, stainless steel 1.4571

Temperature medium-10 to +100°C

ConnectionSee table

270-X

classic

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 50.0 mm

Pressure range 0.00 - 40.0 bar

KV value 2.5 - 47.2 m³/h

Housing materialBrass, Aluminium

Temperature medium -10 to +100°C

Connection G1/4, G3/8, G1/2, G3/4, G1, G1 1/4, G1 1/2, G2

271-X

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 32.0 mm

Pressure range 0.00 - 64.0 bar

KV value 2.5 - 20.0 m³/h

Housing materialBrass, Aluminium

Temperature medium-10 to+100°C

ConnectionG1/4, G3/8, G1/2, G3/4, G1, G1 1/4, G1 1/2

272-X

Design 2/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 32.0 mm

Pressure range 0.00 - 100.0 bar

KV value 2.5 - 20.0 m³/h

Housing material

Brass, aluminum

Temperature medium-10 to +100°C

Connection G1/4, G3/8, G1/2, G3/4, G1, G1 1/4, G1 1/2

390

Design 3/2-way

Actuation type direct controlled

Nominal diameter 10.0 mm - 15.0 mm

Pressure range 0.00 - 20.0 bar

KV value 2.5 - 5.6 m³/h

Housing material brass, stainless steel 1.4305, stainless steel 1.4571

Temperature medium -20 to +40°C

Connection G1/4, G3/8, G1/2, G3/4

Technical details and areas of application

To help you make an informed choice, you will find an overview of the key features of direct-acting valves here.

Advantages:

-

Fast response time: The direct magnetic drive enables extremely fast switching operations.

-

Pressure independent: Full functionality from 0 bar, as no minimum pressure difference is required.

-

Simple design: Fewer components mean high reliability and low maintenance.

-

Compact design: Ideal for installations with limited space.

Disadvantages:

-

Limited flow: Due to its design, not suitable for very large volume flows.

-

Higher energy consumption: For larger nominal diameters, the magnet must apply full force to open.

Typical applications:

Low pressure & vacuum systems: Wherever there is no differential pressure.

Precision controls: For the exact dosing of small quantities of liquid or gas, e.g. in laboratory or medical technology.

Small appliances: In devices such as coffee machines or analytical devices.

Maintenance and installation:

Low maintenance: The simple design with few moving parts ensures a long service life.

Flexible installation: Since no pressure difference is required, the valves can be installed in any position and in any flow direction.

"Precision and speed – directly controlled solenoid valves

for reliable control even at low pressure."

Your contact for high-quality and reliable valve solutions.